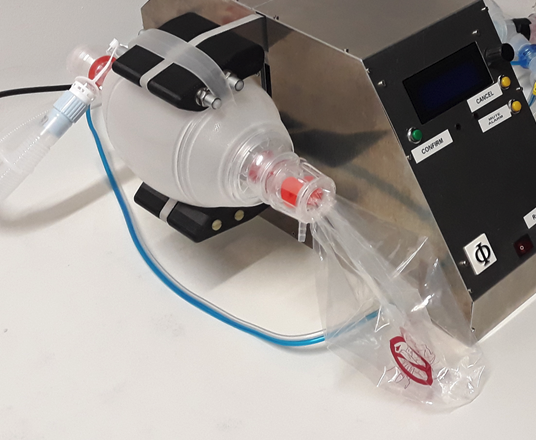

Our chosen approach is based on manual resuscitators, e.g. Ambubags, an elastomer balloon that can be compressed manually to deliver tidal volumes of up to1 l of room air or an oxygen-enriched mixture to intubated adults. Ambubags are for single-patient use, cheap (can be less than ten USD), and available in large quantities in most major healthcare facilities.

Schematic of HDVent system

All components directly in contact with the patient are single-use (orange). An optional monitoring unit (red) can be attached to the main device (blue) to display ventilation parameters, alarm thresholds and time traces.

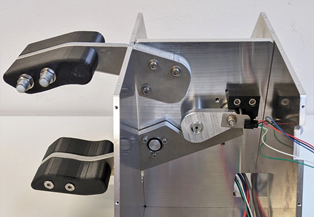

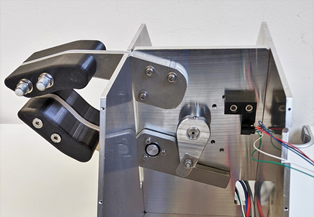

Mechanical compression

The HDVent is designed for a low maintenance, long endurance performance. Driven by a NEMA 34 stepper motor rated at 4 Nm holding torque, the Ambubag can be compressed with low wear and a long lifetime of all mechanical parts. We were strongly inspired by the MIT Emergency Ventilator project.

The compression system consists of two mechanical arms. Both arms are actuated by gear wheels. We fix one arm and allow the other one to rotate on a ball bearing. A second bearing on the end of a crank mounted on the motor shaft runs on the flat upper surface of the pivoting arm, forcing it to rotate. Apart from the off-the-shelf ball bearings the only part subject to friction is the running surface of the actuated arm. This simple design allows manufacturing both the arms and the mounting and base plate from the same 10mm aluminum stock, for example with a water jet. The CAD file for the assembly can be downloaded here.

Air Management

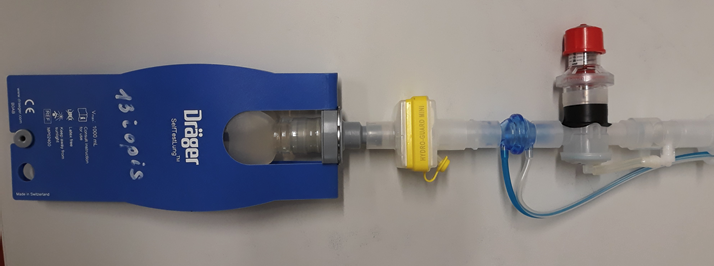

We work with the Dräger Oxylog 2000 Ventstar® breathing circuit and the AmbuSPUR II system, but other resuscitators can be used. The bag takes in room air or optionally oxygen-enriched room air via a reservoir. It is followed by a 40 mbar over-pressure safety valve and 2 metres of flexible hose. Near the patient a membrane Y-Valve separates in- from exhaled air, which is critical to reduce dead volume in the breathing circuit. The open end of the Y-Valve is piloted with a mechanical valve from the Ambubag system to set the positive end-expiratory pressure (PEEP). The flowrate of in- and exhaled air is monitored with a spirometry tube. The pressure is picked up near the patient mouth piece using two thin (2mm ID) hoses connected to the HDvent. We measure the pressure relative to atmosphere and the differential pressure P2 – P1 across a thin mesh in the spirometry tube, which is directly proportional to the flow. A HEPA filter between the valve and the patient ensures that the in- and exhaled air is free of virus material and particulate contaminants. All parts in contact with the patient or breathable air are available commercially and approved for clinical use.