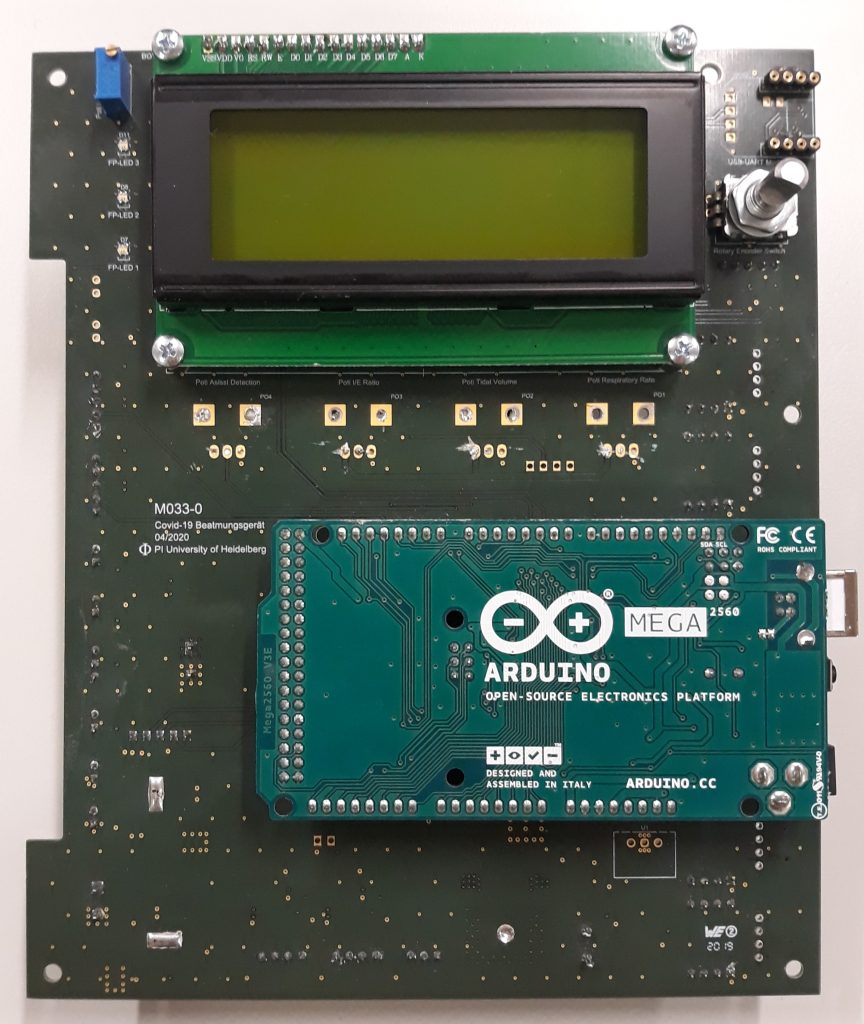

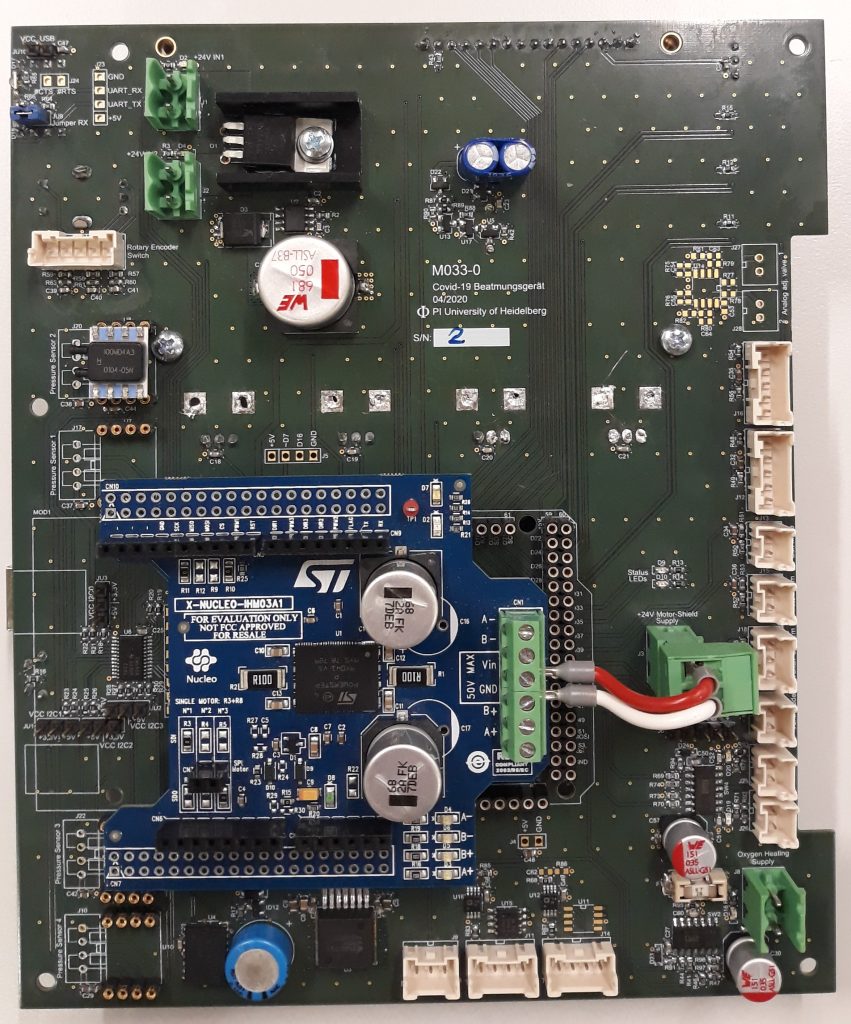

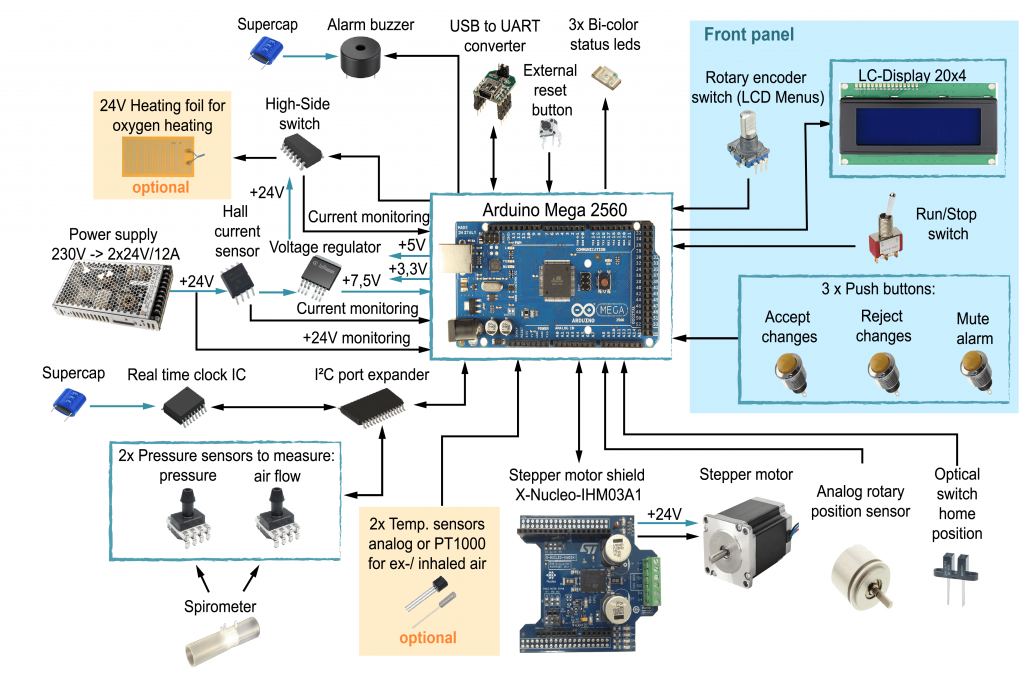

The HDVent is controlled by an ATMega2560 microcontroller equipped on an Arduino Mega 2560 board, which handles motor control, user input, sensor readings, power management and data flow. The microcontroller is mounted on a custom PC board that implements all peripheral electronics and provides convenient access to the digital and analog outputs of the Arduino board, connections to the sensors, and buffered outputs. The motor is controlled via the powerSTEP01 stepper controller chip on an evaluation board, which supports microstepping up to 1/128, features a sensorless stall detection and is controlled via an SPI interface. The following figures show an overview of the implemented features and photographs of the custom-made board.

For pressure and flow measurements, we use two board-mounted differential pressure sensors from the Honeywell HSC series, a line of high precision pressure sensors for medical applications. The sensors are connected to the outside of the chassis via pick-up hoses and a custom-made feedthrough for Dräger tubing. The volume flow measurement is realized as a differential pressure measurement across a spirometer tube. We selected a sensor with a range of ±100 mbar for the inspiratory pressure measurement and a second sensor with a finer range of ± 16 mbar for the spirometry.

In addition to these clinically relevant measurements, several sensors monitor the proper operation of the device: An optical switch defines the home position of the stepper and an analog resistive rotation sensor coupled to the motor shaft allows absolute measurements of the stepper position. A Hall current sensor monitors the built-in 24 V modular power supply.